Table of Contents

1. Introduction

2. Understanding Composite Insulators

3. Key Advantages of Composite Insulators

3.1 Enhanced Efficiency

3.2 Improved Durability

3.3 Lightweight and Easy Installation

3.4 Resistance to Harsh Environmental Conditions

4. Applications of Composite Insulators

4.1 Power Transmission and Distribution

4.2 Substations and Switchyards

4.3 Railways and Transportation

4.4 Renewable Energy Systems

5. Frequently Asked Questions

5.1 Are composite insulators cost-effective?

5.2 Can composite insulators withstand extreme temperatures?

5.3 How long do composite insulators last?

5.4 Can composite insulators be retrofitted into existing systems?

5.5 Do composite insulators require special maintenance?

6. Conclusion

1. Introduction

In today's rapidly evolving electrical industry, efficiency and reliability are paramount. One innovation that has been gaining traction is the use of composite insulators. These insulators, made from a combination of different materials, offer a range of benefits that traditional insulators cannot match. In this article, we will explore how composite insulators improve efficiency in electrical systems and why they are becoming the go-to choice for many industry professionals.

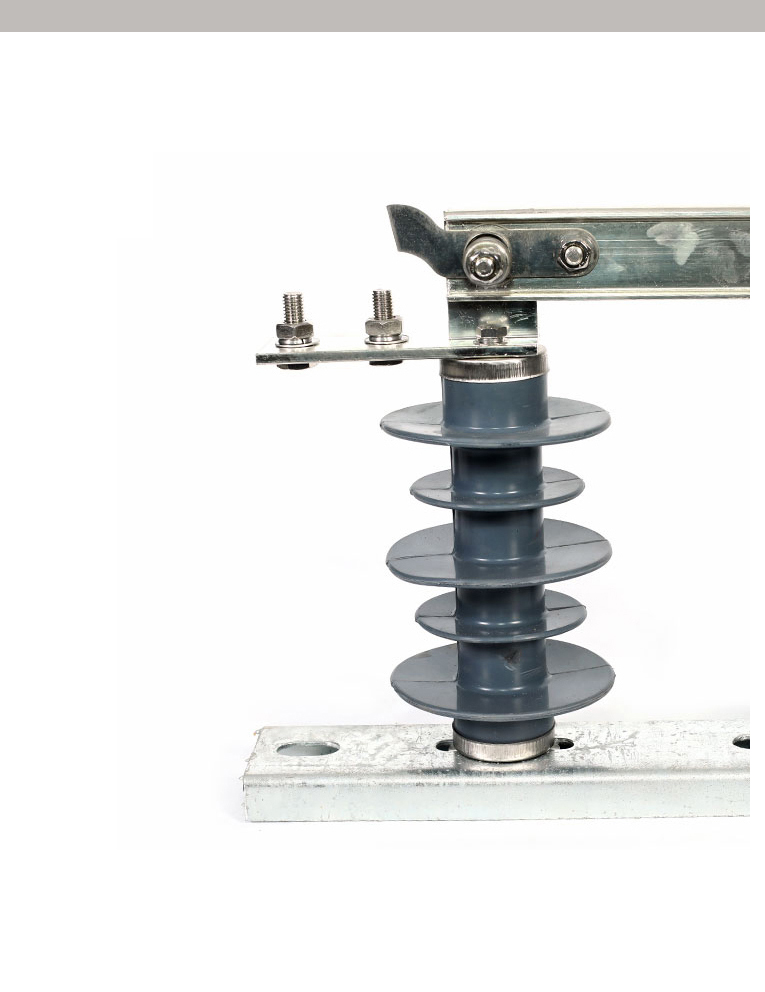

2. Understanding Composite Insulators

Composite insulators are insulating devices used to support and insulate conductors in electrical systems. Unlike their traditional porcelain or glass counterparts, composite insulators are made from a combination of materials such as fiberglass rods, silicone rubber, and metal fittings. This unique composition grants them several advantageous properties, making them highly desirable in various applications.

3. Key Advantages of Composite Insulators

3.1 Enhanced Efficiency

One of the primary benefits of composite insulators is their ability to improve efficiency in electrical systems. Their lightweight construction reduces the overall weight of transmission lines, resulting in reduced sag and improved power transmission. This efficiency improvement translates to less energy loss and more reliable performance, ultimately leading to cost savings for power utilities and consumers.

3.2 Improved Durability

Composite insulators are highly durable and can withstand extreme weather conditions, including high temperatures, humidity, and UV radiation. Unlike porcelain insulators, composite insulators are not susceptible to cracking or chipping, ensuring a longer service life. Their robust construction also makes them resistant to vandalism and reduces the risk of insulation failure, enhancing the overall reliability of electrical systems.

3.3 Lightweight and Easy Installation

Compared to traditional insulators, composite insulators are significantly lighter, making them easier to handle and install. This characteristic simplifies the installation process and reduces labor requirements, resulting in cost savings for utility companies. Additionally, the lightweight nature of composite insulators minimizes the mechanical stress on support structures, further enhancing their lifespan and performance.

3.4 Resistance to Harsh Environmental Conditions

Composite insulators excel in harsh environmental conditions, making them ideal for use in coastal areas, polluted environments, and areas prone to seismic activities. The non-porosity of composite materials prevents the accumulation of dirt and pollutants, ensuring consistent performance over time. Furthermore, their excellent hydrophobic properties make them resistant to water absorption, reducing the risk of flashovers and electrical failures.

4. Applications of Composite Insulators

4.1 Power Transmission and Distribution

Composite insulators are extensively used in power transmission and distribution systems. Their efficiency, durability, and ability to withstand high electrical and mechanical stresses make them ideal for supporting overhead power lines. By reducing energy losses and improving reliability, composite insulators play a crucial role in ensuring uninterrupted power supply to consumers.

4.2 Substations and Switchyards

In substations and switchyards, where electrical equipment is interconnected and controlled, composite insulators find applications in various components such as circuit breakers, transformers, and busbars. Their excellent electrical insulation properties and resistance to outdoor conditions make them a reliable choice for critical infrastructure, ensuring safe and efficient operation.

4.3 Railways and Transportation

Composite insulators are also widely used in railway electrification systems and transportation infrastructure. Their lightweight construction and resistance to environmental factors make them suitable for catenary wires, overhead lines, and other electrical components. By improving the efficiency and reliability of railway systems, composite insulators contribute to sustainable and safe transportation.

4.4 Renewable Energy Systems

As the demand for renewable energy sources grows, composite insulators play a vital role in supporting and insulating wind turbines, solar power systems, and other renewable energy infrastructure. Their ability to withstand harsh weather conditions, high-voltage requirements, and mechanical stresses makes them an excellent choice for renewable energy applications.

5. Frequently Asked Questions

5.1 Are composite insulators cost-effective?

Yes, composite insulators offer cost savings in the long run due to their enhanced performance, reduced maintenance requirements, and longer service life compared to traditional insulators.

5.2 Can composite insulators withstand extreme temperatures?

Yes, composite insulators are designed to withstand a wide range of temperatures, from extreme cold to high heat, without compromising their performance.

5.3 How long do composite insulators last?

Composite insulators have a significantly longer lifespan compared to porcelain or glass insulators. With proper maintenance, they can last 30 years or more.

5.4 Can composite insulators be retrofitted into existing systems?

Yes, composite insulators can be retrofitted into existing systems without major modifications, making them a versatile solution for upgrading aging infrastructure.

5.5 Do composite insulators require special maintenance?

Composite insulators require minimal maintenance compared to traditional insulators. Periodic visual inspections and cleaning are usually sufficient to ensure optimal performance.

6. Conclusion

Composite insulators have emerged as a game-changer in the electrical industry, offering enhanced efficiency, durability, and versatility. From power transmission to renewable energy systems, their unique properties make them an ideal choice for optimizing the performance of electrical infrastructure. By investing in composite insulators, power utilities and consumers can enjoy improved reliability, reduced energy losses, and long-term cost savings. Stay ahead of the curve and embrace the benefits of composite insulators in your electrical systems.

1. Introduction

2. Understanding Composite Insulators

3. Key Advantages of Composite Insulators

3.1 Enhanced Efficiency

3.2 Improved Durability

3.3 Lightweight and Easy Installation

3.4 Resistance to Harsh Environmental Conditions

4. Applications of Composite Insulators

4.1 Power Transmission and Distribution

4.2 Substations and Switchyards

4.3 Railways and Transportation

4.4 Renewable Energy Systems

5. Frequently Asked Questions

5.1 Are composite insulators cost-effective?

5.2 Can composite insulators withstand extreme temperatures?

5.3 How long do composite insulators last?

5.4 Can composite insulators be retrofitted into existing systems?

5.5 Do composite insulators require special maintenance?

6. Conclusion

1. Introduction

In today's rapidly evolving electrical industry, efficiency and reliability are paramount. One innovation that has been gaining traction is the use of composite insulators. These insulators, made from a combination of different materials, offer a range of benefits that traditional insulators cannot match. In this article, we will explore how composite insulators improve efficiency in electrical systems and why they are becoming the go-to choice for many industry professionals.

2. Understanding Composite Insulators

Composite insulators are insulating devices used to support and insulate conductors in electrical systems. Unlike their traditional porcelain or glass counterparts, composite insulators are made from a combination of materials such as fiberglass rods, silicone rubber, and metal fittings. This unique composition grants them several advantageous properties, making them highly desirable in various applications.

3. Key Advantages of Composite Insulators

3.1 Enhanced Efficiency

One of the primary benefits of composite insulators is their ability to improve efficiency in electrical systems. Their lightweight construction reduces the overall weight of transmission lines, resulting in reduced sag and improved power transmission. This efficiency improvement translates to less energy loss and more reliable performance, ultimately leading to cost savings for power utilities and consumers.

3.2 Improved Durability

Composite insulators are highly durable and can withstand extreme weather conditions, including high temperatures, humidity, and UV radiation. Unlike porcelain insulators, composite insulators are not susceptible to cracking or chipping, ensuring a longer service life. Their robust construction also makes them resistant to vandalism and reduces the risk of insulation failure, enhancing the overall reliability of electrical systems.

3.3 Lightweight and Easy Installation

Compared to traditional insulators, composite insulators are significantly lighter, making them easier to handle and install. This characteristic simplifies the installation process and reduces labor requirements, resulting in cost savings for utility companies. Additionally, the lightweight nature of composite insulators minimizes the mechanical stress on support structures, further enhancing their lifespan and performance.

3.4 Resistance to Harsh Environmental Conditions

Composite insulators excel in harsh environmental conditions, making them ideal for use in coastal areas, polluted environments, and areas prone to seismic activities. The non-porosity of composite materials prevents the accumulation of dirt and pollutants, ensuring consistent performance over time. Furthermore, their excellent hydrophobic properties make them resistant to water absorption, reducing the risk of flashovers and electrical failures.

4. Applications of Composite Insulators

4.1 Power Transmission and Distribution

Composite insulators are extensively used in power transmission and distribution systems. Their efficiency, durability, and ability to withstand high electrical and mechanical stresses make them ideal for supporting overhead power lines. By reducing energy losses and improving reliability, composite insulators play a crucial role in ensuring uninterrupted power supply to consumers.

4.2 Substations and Switchyards

In substations and switchyards, where electrical equipment is interconnected and controlled, composite insulators find applications in various components such as circuit breakers, transformers, and busbars. Their excellent electrical insulation properties and resistance to outdoor conditions make them a reliable choice for critical infrastructure, ensuring safe and efficient operation.

4.3 Railways and Transportation

Composite insulators are also widely used in railway electrification systems and transportation infrastructure. Their lightweight construction and resistance to environmental factors make them suitable for catenary wires, overhead lines, and other electrical components. By improving the efficiency and reliability of railway systems, composite insulators contribute to sustainable and safe transportation.

4.4 Renewable Energy Systems

As the demand for renewable energy sources grows, composite insulators play a vital role in supporting and insulating wind turbines, solar power systems, and other renewable energy infrastructure. Their ability to withstand harsh weather conditions, high-voltage requirements, and mechanical stresses makes them an excellent choice for renewable energy applications.

5. Frequently Asked Questions

5.1 Are composite insulators cost-effective?

Yes, composite insulators offer cost savings in the long run due to their enhanced performance, reduced maintenance requirements, and longer service life compared to traditional insulators.

5.2 Can composite insulators withstand extreme temperatures?

Yes, composite insulators are designed to withstand a wide range of temperatures, from extreme cold to high heat, without compromising their performance.

5.3 How long do composite insulators last?

Composite insulators have a significantly longer lifespan compared to porcelain or glass insulators. With proper maintenance, they can last 30 years or more.

5.4 Can composite insulators be retrofitted into existing systems?

Yes, composite insulators can be retrofitted into existing systems without major modifications, making them a versatile solution for upgrading aging infrastructure.

5.5 Do composite insulators require special maintenance?

Composite insulators require minimal maintenance compared to traditional insulators. Periodic visual inspections and cleaning are usually sufficient to ensure optimal performance.

6. Conclusion

Composite insulators have emerged as a game-changer in the electrical industry, offering enhanced efficiency, durability, and versatility. From power transmission to renewable energy systems, their unique properties make them an ideal choice for optimizing the performance of electrical infrastructure. By investing in composite insulators, power utilities and consumers can enjoy improved reliability, reduced energy losses, and long-term cost savings. Stay ahead of the curve and embrace the benefits of composite insulators in your electrical systems.